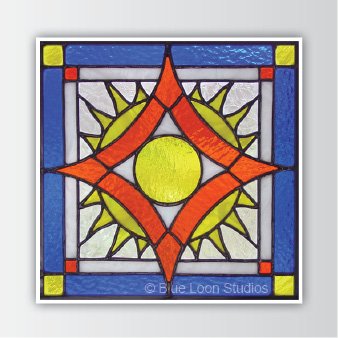

stained glass

The term stained glass refers to colored glass, or the works created from it. Although traditionally made in flat panels and displayed in windows, the creations of modern stained glass artists also include three-dimensional structures

Glass is made by mixing together some form of silica such as sand, an alkali such as potash or soda, and lime or lead oxide.

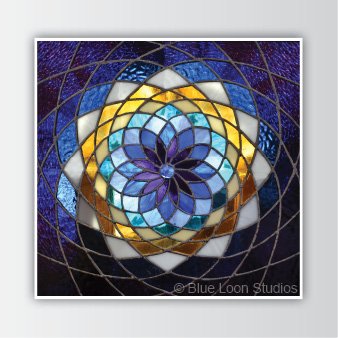

The color is produced by adding a metallic oxide to the raw materials. The mix is then melted in a furnace at 2500°F, and the molten glass is ladled into a machine that rolls the glass into 1/8-inch thick sheets. The sheets are then cooled in a special furnace called an annealing lehr.

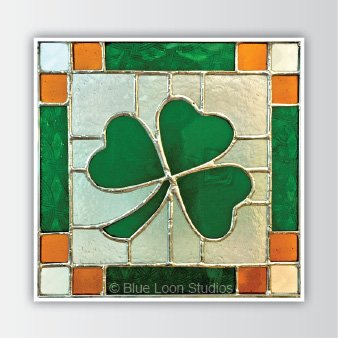

The process for making an entire stained glass window can take anywhere from seven to ten weeks, since everything must be done by hand. Cost can vary widely depending on complexity, size, and choice of glass.

The first step of the process involves creating a workable design, or pattern. This pattern is drawn or reproduced on paper or cardboard. It is cut along the black or lead lines with double-bladed scissors which, as they passes through the middle of the black lines, simultaneously cut away a narrow strip of paper, allowing sufficient space between the pieces of glass for the lead solder.

The pattern pieces are placed on a piece of the desired glass, and with a diamond wheel, the glass is cut to the shape of the pattern. Grinding is done in order to even out the edges of the glass and ensure the shape of the glass matches the pattern piece.

The Copper Foil technique is mainly used in the construction of relatively smaller pieces, and it was, in fact, frequently used by Louis Comfort Tiffany. It consists of wrapping the cut pieces of glass in a self-adhesive tape that is made out of thin copper foil. After the glass pieces have been foiled, they are soldered together with lead, and a sturdy zinc frame and hanging hooks are added to form the finished piece.